Wisconsin Precision CNC Milling Service

Expertise in Horizontal & Vertical Milling

With expertise in horizontal and vertical CNC milling services and full 4-axis capabilities, Mahuta Tool is a trusted partner for a wide range of industries throughout the Midwest. Our CNC milling services produce everything from fittings and spacers to turbine and engine parts. We have an ISO 9001:2015 certified quality management system. Our machine shop is registered as Mil-Spec compliant and we work to tolerances as close as ±.0001.”

Rush jobs and emergency services are available. For information, call 888-686-4940.

Why Choose Mahuta Tool for CNC Milling?

We specialize in short-run and prototype production of both metal and plastic products. Many of our clients find their way to Mahuta Tool when they have trouble locating a CNC milling company willing to take on a difficult job. Businesses don’t choose us because we underbid everyone, they choose us because they know we get the job done right. Fair pricing and quick turnarounds on precision-crafted parts are what keep our clients coming back.

What is CNC Milling?

CNC milling is a precise manufacturing process that utilizes computer numerical control (CNC) technology to remove material from a workpiece using rotary cutting tools. It involves mounting a block of raw material onto a table, where it is then meticulously shaped and carved to create intricate parts and components. With the ability to operate on multiple axes, CNC milling machines offer unparalleled precision and versatility, making them indispensable in industries ranging from aerospace to electronics.

Our CNC Milling Capabilities

At Mahuta Tool, we boast comprehensive CNC milling capabilities to meet the diverse needs of our clients. Whether it's crafting complex prototypes or producing high-volume parts, our state-of-the-art equipment and skilled machinists ensure exceptional quality and accuracy in every project.

Vertical CNC Milling

At Mahuta Tool, our vertical CNC milling services offer exceptional precision and versatility to meet the demands of diverse industries. Our state-of-the-art equipment is equipped with 5-axis machining capabilities, allowing us to create complex geometries and intricate designs with ease. Whether it's producing small, intricate components or larger parts, our vertical milling machines deliver unparalleled accuracy and efficiency.

With a maximum machining envelope of 84" in length, 32" in width, and 30" in height, we can handle a wide range of part sizes and configurations. Our experienced machinists utilize advanced CAD/CAM software to program the machining operations, ensuring optimal tool paths and efficient material removal. From rapid prototyping to high-volume production, our vertical CNC milling services are tailored to meet the unique needs of each project, delivering superior results every time.

Vertical Milling Capabilities

- Drilling

- Boring

- Counterboring

- Pocketing

- Profiling

- Reaming

- Tapping

Horizontal CNC Milling

Mahuta Tool's horizontal CNC milling capabilities are second to none, offering precision machining solutions for a variety of applications. Our horizontal milling machines are equipped with 4-axis machining capabilities, enabling us to produce parts with complex contours and features. With a maximum machining envelope of 64" in length, 40" in width, and 32" in height, we can accommodate a wide range of part sizes and configurations.

Our skilled machinists leverage the latest CNC technology and tooling to achieve tight tolerances and superior surface finishes. Whether it's machining large structural components or small precision parts, our horizontal milling services deliver exceptional results with efficiency and accuracy. From prototype development to full-scale production runs, Mahuta Tool is committed to meeting the unique needs of each customer with precision and reliability.

Horizontal Milling Capabilities

- Drilling

- Boring

- Reaming

- Tapping

- Milling of metals and plastics (nylon, teflon, polycarbonate)

Prototype CNC Milling

We understand the importance of rapid prototyping in product development, which is why our prototype CNC milling services are tailored to meet the demands of fast-paced industries. From concept to completion, our experienced team collaborates closely with clients to bring their ideas to life with precision and speed.

Large & Short Run CNC Milling

Whether it's a large-scale production run or a short batch of parts, Mahuta Tool is equipped to handle projects of any size. Our efficient manufacturing processes and commitment to quality enable us to deliver consistent results, regardless of volume, ensuring customer satisfaction every time.

Common Industries We CNC Mill Parts

CNC Milling for the Medical Industry

In the medical industry, precision is paramount. Our CNC milling services cater to the unique requirements of medical device manufacturers, delivering components with tight tolerances and exceptional quality. From surgical instruments to implantable devices, we ensure compliance with stringent regulatory standards and stringent quality control measures.

CNC Milling for the Automotive Industry

With our extensive experience in CNC milling, Mahuta Tool is a trusted partner for automotive manufacturers seeking reliable machining solutions. From engine components to intricate automotive parts, we deliver precision-machined components that meet the rigorous demands of the automotive industry.

CNC Milling for the Aerospace Industry

The aerospace industry demands uncompromising precision and reliability, and our CNC milling services are tailored to meet these exacting standards. From structural components to aerospace-grade materials, we have the expertise and capabilities to produce parts that meet the stringent requirements of aerospace applications.

Meet Our CNC Milling Machines

DMG Mori CMX 70 U 5-Axis

CMX U series realizes high-productivity, flexibility and operatively with the modern C-frame design. Integrated NC-controlled B- and C-axis table and inherently stable, mineral cast composite bed delivers maximum stability. This applies to the modularity and possibility to build up “your own machine” with wide range of hardware and software options, variety of 3D-controls and technological solutions.

29.5” X 23.5” X 20.5”

Vertical

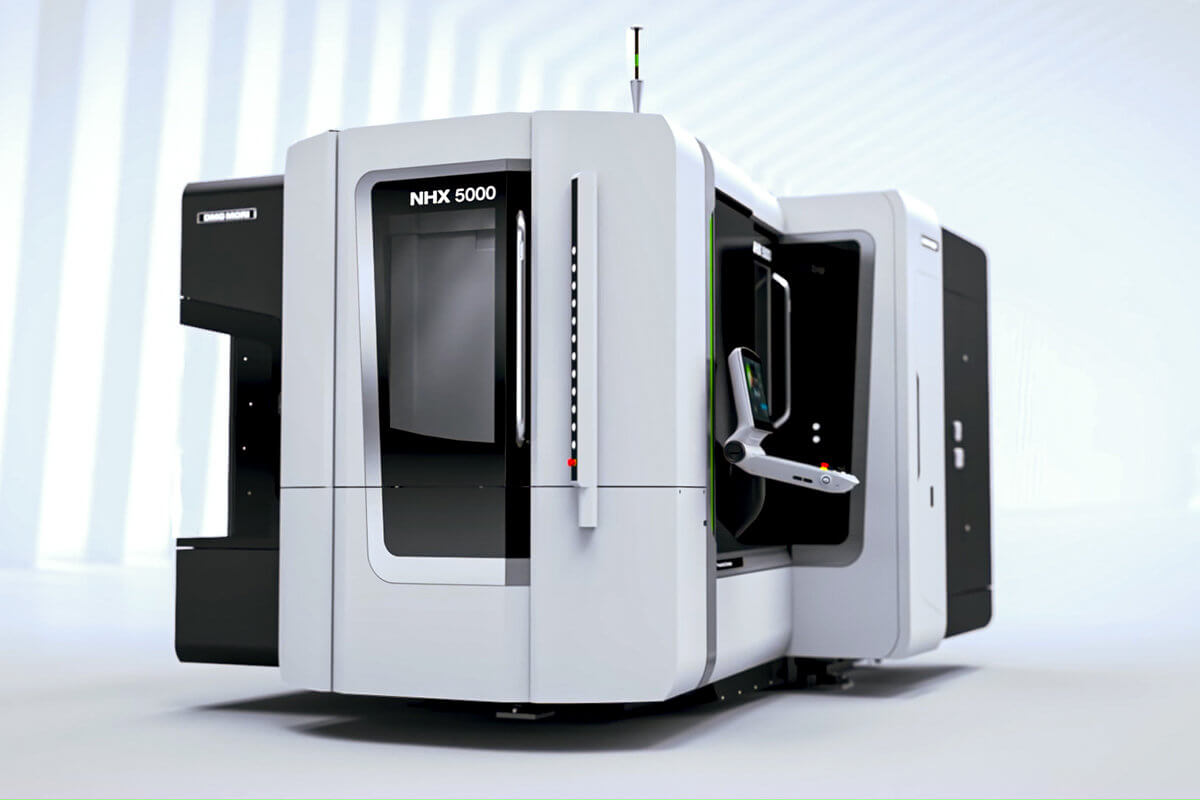

DMG Mori NHX5000

DMG Mori's NHX5000 is a horizontal machining center with the highest stability, precision and dynamics the industry has to offer. This machine presents a compact general-purpose machining center, enabling highly efficient continuous machining and mass production machining.

28.7" x 28.7" x 34.6"

Horizontal

DMG Mori CMX 1100V 5 Axis

DMG Mori's CMX 1000V 5-axis provides precision in every component and detail. It’s capable of positioning accuracy down to 0.00023 inches on all axes. This machine's sophisticated design provides a small footprint and large working area, making it perfect for any manufacturing environment.

43/3" x 22" x 20.1"

Vertical

HAAS EC-1600 HMC

Thanks to a large work cube and a maximum part capacity of 10,000 lb., the Haas EC-1600 is the perfect solution for any large-part machining requirements. For this reason, the EC-1600 is one of the more popular 3-axis machines on the market.

62" x 40" x 32"

Full Axis Rotary

HAAS VF-7/41 with 4th Axis

As a member of Haas' industry leading VF Series, this machine is one of the best-value, high-performance machine tools available. The VF-7 allows for machining of high-quality large parts.

84" x 32" x 30"

Vertical

HAAS VF-3 with 4th Axis

As a member of the Haas VF Series family, this machine is an industry leader in high-performance machine tools. The VF-3 features a larger work envelope than the VF-1 and VF-2, allowing for machining of medium sized, high-quality parts.

40" x 20" x 25"

Vertical

HAAS VF-2 with 4th Axis

Every VF Series model from Haas provides excellent features at a great price. The VF-2 is their most popular model, an outstanding machine for any small-part machining, and a superb addition to any machine shop.

30" x 16" x 20"

Vertical

HAAS VF-2 Super Speed with 4th Axis

Haas' high-performance Super-Speed vertical machining centers provide high spindle speeds and quick tool changes required for high-volume production. This machine features extended Y-axis travel over the standard VF-2, and makes for a great addition to any high-speed machining workshop.

30" x 16" x 20"

Vertical

Fadal VMC-15XT

The Fadal VMC-15XT is a reliable small-sized machine designed for part production and heavy metal removal. This machine is built to perform high material removal rates and reduced cycle times, while holding increased positioning accuracy and repeatability.

16" x 30" x 20"

Vertical

HAAS Mini Mill

Haas' Mini Mill has set the industry standard for compact machining centers. They’re an economical solution for exclusive small-part machining in a compact package with all the full-size features. This machine is perfect for CNC education, start-up shops, or as a first step into CNC machining.

16" x 12" x 10"

Vertical